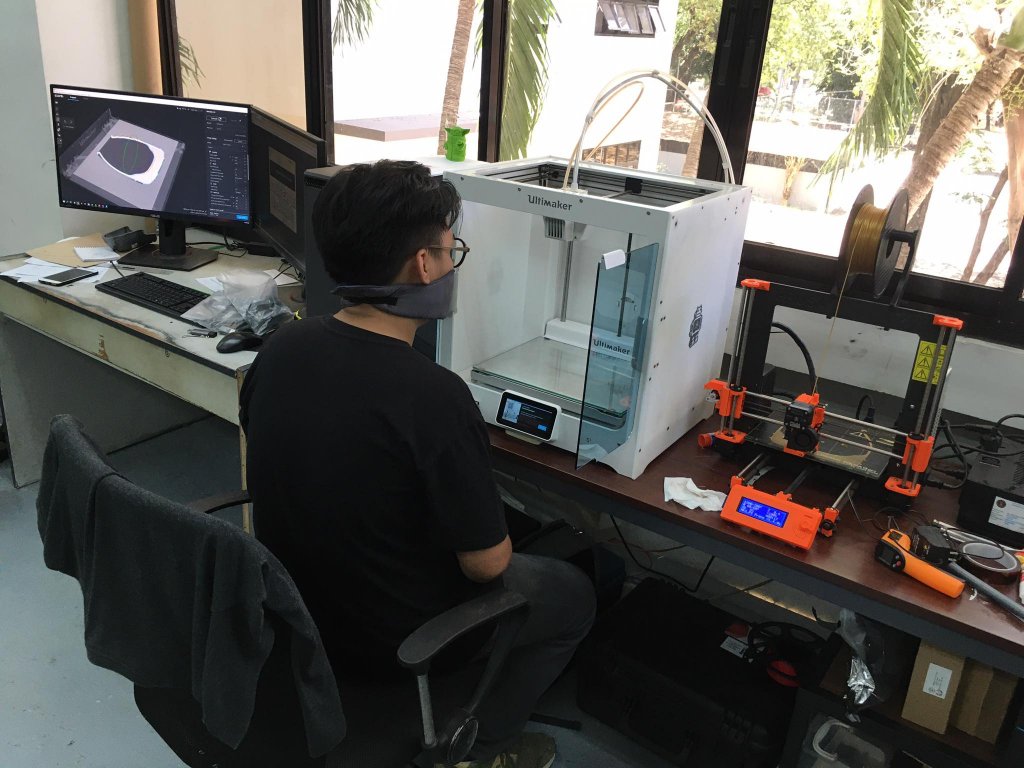

A team of faculty members and staff at the University of the Philippines Cebu FabLab has designed and started 3D-printing face shield frames to contribute to the much-needed supply of personal protective equipment (PPE) in the fight against COVID-19.

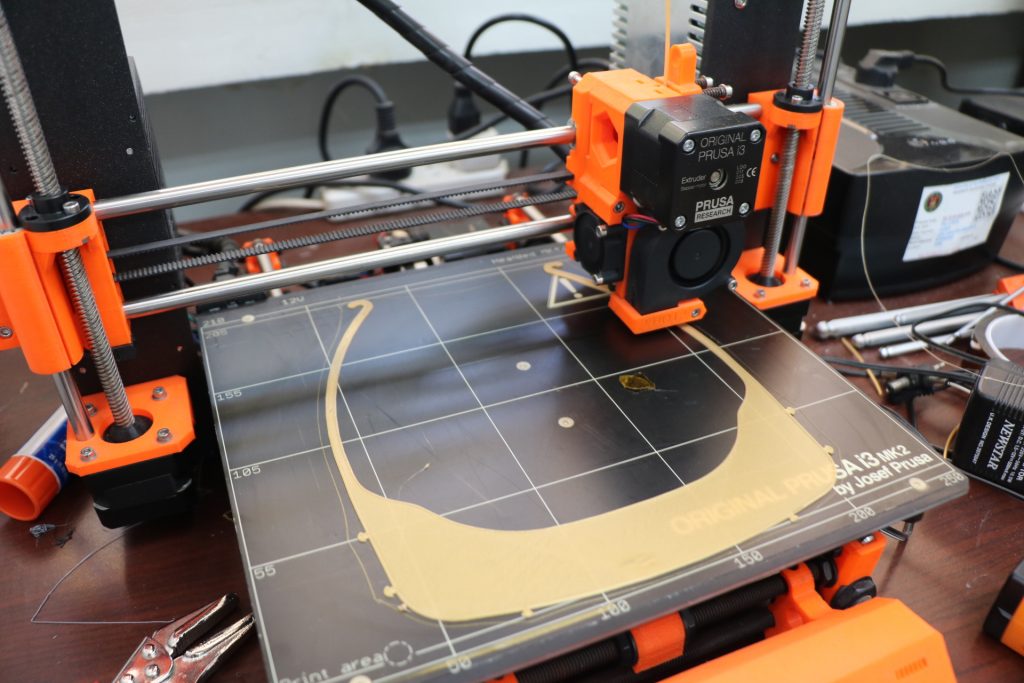

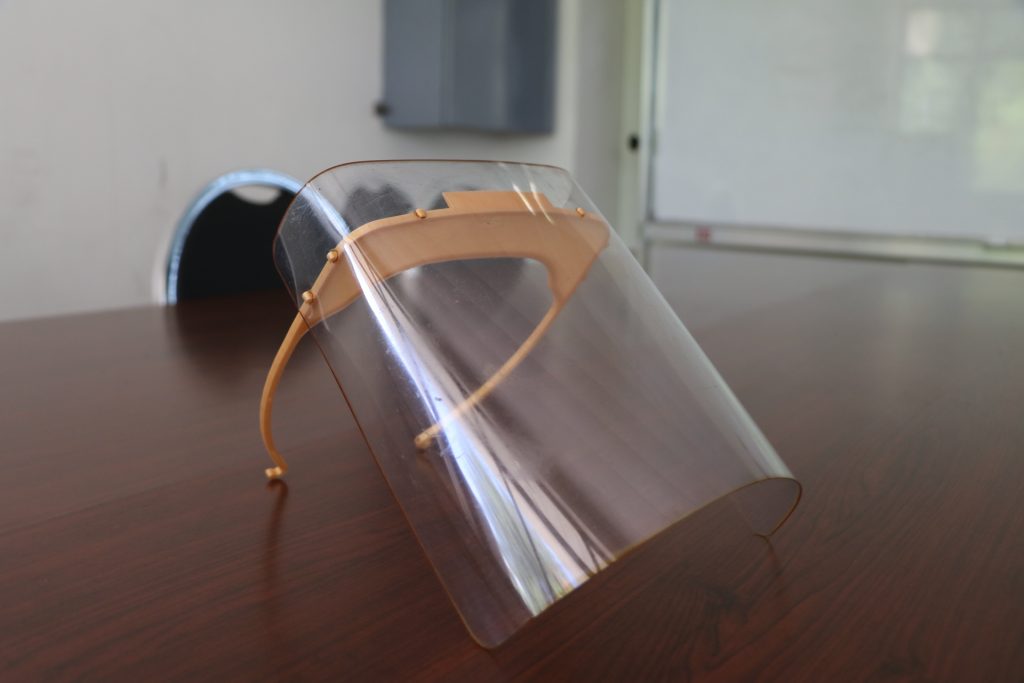

The frame can be attached to a sheet of plastic or acetate to create a face shield that helps protect Cebu’s frontline health workers and other users against the coronavirus. Prototyping of the frame was initially created using a 3D printer but after a few tests they found out that using a laser cutter was much faster and yielded more results.

The FabLab will be operating at regular office hours to work on producing as much face shields for the Cebu community. Procurement of additional materials is already underway.

Initially backed by funds from UP Cebu Education and Research Foundation Inc. (UPCERFI) and the laboratory’s own resources including its modern fabrication tools, the team is expected to receive additional materials for making the frames from the Department of Trade and Industry. It also welcomes support from private donors, once a final model will be made that is ready for mass production.

Note that UP Cebu will not be accepting donations, but only through UPCERFI.

The team is composed of the College of Communication, Art, and Design dean Prof. Palmy Marinel Tudtud, Prof. Mona Alcudia, Prof. Jay Nathan Jore, Fidel Laurence Ricafranca, Mark Argel Simacon, and Prof. Raymund Fernandez.

A fab lab or fabrication laboratory is a makerspace or small-scale workshop that is equipped “with an array of flexible computer-controlled tools that cover several different length scales and various materials.”

As a global network of local labs, fab labs share an evolving inventory of core capabilities to make (almost) anything, allowing people and projects to be shared.

Photos by Vanessa Guerrero and Prof. Mona Alcudia

Using a 3D printer, the initial prototype is made.

3D printed base and acetate put together to make the first prototype.

UP Cebu faculty and FabLab maker, Fidel Ricafranca, and Dr. Dee brainstorm on design of PPEs.

UP Cebu Medical Officer, Dr. Dee offers her inputs on how to better the protective capabilities of the PPE.

Options for materials and design of PPE.